Steel Industry in the UK: Why 2026 Is a Turning Point, Not a Decline

Headlines still shout closures and costs, but a quieter story is breaking through the noise. From fresh government backing to green steel investment and rising demand from defence and infrastructure, the UK steel industry is shifting gears.

What looks like decline from a distance is starting to resemble a reset—one that makes 2026 a pivotal year worth paying attention to.

But here’s the part almost no one tells you.

2026 is not the end of British steel. It’s the reset.

The UK steel industry is smaller than it was. That’s true. But it is also more strategic, more politically protected, and more central to Britain’s future than at any point in the last 30 years. Steel now sits at the intersection of national security, net-zero policy, housing targets, rail upgrades, and offshore wind.

This is your 2026 guide to the steel industry in the UK: where it really stands, who’s still producing, what’s changing, and why steel matters more than the headlines suggest.

Steel in the UK in 2026: the numbers that matter

Let’s ground this in facts, not nostalgia.

- 37,000 people are directly employed in the UK steel industry.

- The sector contributes around £1.7 billion in Gross Value Added to the UK economy.

- The UK produces roughly 5.6 million tonnes of crude steel a year.

- There are over 1,100 steel businesses across the country, from mills to fabricators.

That’s just 0.1% of total UK GDP. Small on paper.

But steel punches far above its weight. Construction, rail, defence, automotive, aerospace, offshore wind, energy infrastructure and housing all depend on it. When steel fails, entire supply chains stall.

The Scunthorpe moment: why government stepped in

If you want to understand why steel matters in 2026, look at Scunthorpe.

In April 2025, Parliament was recalled in an emergency session. The reason? To stop the immediate shutdown of British Steel’s blast furnaces in Scunthorpe — the UK’s last producer of virgin steel from raw materials.

The government used emergency powers to keep the furnaces running, commit hundreds of millions of pounds in support, and secure domestic steel production for rail, housing and national infrastructure.

This wasn’t nostalgia. It was strategy.

By late 2025, a £500 million Network Rail contract was agreed, guaranteeing British Steel would supply more than 330,000 tonnes of rail over five years. That single deal underlined a new reality: steel is now considered a critical national capability.

Steel manufacturing companies and key locations

The UK steel industry today is concentrated, specialised, and regionally anchored.

- Steel Benders Middlesbrough – Specialist bending and shaping for construction and heavy industry.

- Steel manufacturers in London – Smaller, high-value fabrication and processing firms rather than primary steelmaking.

- British Steel Scunthorpe – Long products, rail, wire rod and the UK’s last blast furnaces (transitioning).

- Liberty Steel Rotherham & Wednesbury – Speciality steels and engineering bar.

- Cleveland Steel Thirsk – Stockholding and processing with a strong sustainability focus.

Steel tube manufacturers and suppliers

Steel tube production remains a quiet strength of UK manufacturing, supporting construction, energy and engineering.

| Type | Typical use |

|---|---|

| Seamless steel tube | High-pressure and structural applications |

| Large diameter steel pipe | Infrastructure, water and energy projects |

| Square & rectangular tube | Structural frames and fabrication |

| Thin wall stainless tube | Medical, food and lightweight engineering |

Sheet metal fabrication: where most steel jobs actually are

Here’s the surprise: most UK steel workers don’t work in giant mills.

They work in sheet metal shops, fabrication yards, and regional manufacturers turning steel into usable products.

- Sheet metal fabrication across the UK supports construction, retail fit-outs and industrial equipment.

- London-based fabricators focus on architectural and bespoke work.

- Precision forming and CNC cutting dominate modern workshops.

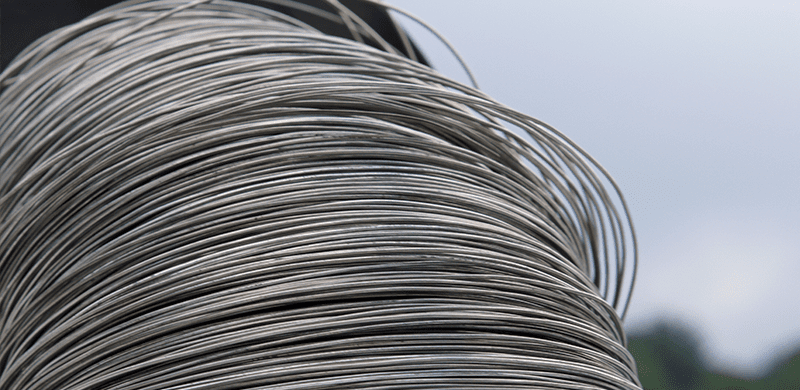

Steel fabrication, wire and casting

Beyond sheets and beams, UK firms specialise in high-value steel components.

- Steel wire for construction, automotive and electronics

- Stainless steel castings for aerospace, medical and defence

- Specialist foundries producing low-volume, high-spec parts

Green steel: the real future of UK steel

This is where everything converges.

By 2026, both British Steel and Tata Steel are moving toward electric arc furnaces (EAFs), replacing coal-based blast furnaces. These can cut emissions by up to 75% and rely heavily on recycled scrap steel.

The UK government has committed billions through industrial strategy, public procurement and green transition funding. Offshore wind alone is expected to require 25 million tonnes of steel by 2050 — a potential £21 billion market.

The steel industry isn’t shrinking into irrelevance. It’s narrowing its focus to where Britain needs it most.

The real takeaway

At the start, we said most people think UK steel is dying.

Now you can see the truth.

The UK no longer tries to outproduce China. It protects capacity, secures supply chains, and invests where steel underpins national priorities. In 2026, steel isn’t about volume. It’s about control.

And that makes British steel more important than it’s been in decades.